{{ translate[LANG].title }}

Smarter Energy Use Through Variable Speed Drives

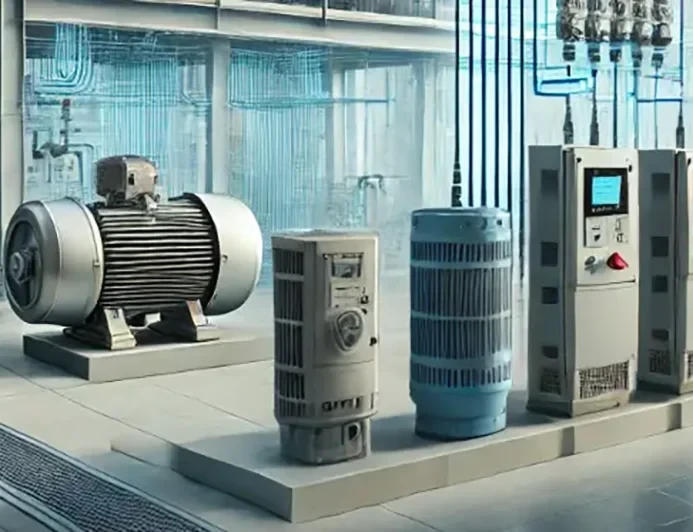

In modern industrial automation, Variable Speed Drives (VSDs) — also known as frequency converters — are one of the most effective tools for reducing electrical energy consumption.

By controlling motor speed according to process demand, VSDs minimize wasted energy, reduce CO₂ emissions, and extend equipment lifespan.

At DAS Company, our engineers design and commission VSD-based control systems that maximize energy efficiency and ensure operational reliability across various industries.

The Engineering Principle Behind VSDs

Most industrial motors run at constant speed — even when full power isn’t needed. This leads to significant energy waste, especially in variable load applications such as pumps, fans, and compressors.

A Variable Speed Drive regulates the motor’s speed and torque by adjusting the frequency and voltage of the power supply.

Mathematically, energy savings follow the cube law:

Power ∝ Speed³

That means a 20% reduction in speed can result in nearly 50% less energy use — a principle DAS Company applies in real industrial systems daily.

Energy Efficiency in Pump and Fan Systems

Pumps and fans are the largest energy consumers in many facilities. Using VSDs in these systems allows:

DAS Company has implemented VSD solutions in HVAC, water treatment, and chemical processing plants, achieving up to 60% reduction in energy costs and longer motor life cycles.

Reduced Mechanical Stress and Maintenance

Beyond electrical savings, VSDs contribute to mechanical reliability:

This results in fewer maintenance interventions and lower total cost of ownership, aligning with E-DAS’s goal of building sustainable, long-life systems.

Power Factor and Network Stability

VSDs also help improve power quality by maintaining a near-unity power factor.

They reduce reactive power demand, lowering transformer loading and cable losses.

When combined with harmonic filters or Low Harmonic Drives (LHDs), overall system stability and grid compatibility increase — something DAS Company considers in every large-scale commissioning project.

Integration with Automation and Monitoring Systems

Modern VSDs support a wide range of industrial communication protocols, such as:

Through these networks, energy data and drive performance are monitored in real time.

DAS Company engineers integrate this data into SCADA and energy management systems, enabling predictive analysis, process optimization, and transparent reporting of energy consumption trends.

Sustainability and Smart Factory Vision

Variable Speed Drives are a cornerstone of the smart factory — supporting digital transformation and sustainable development goals.

By combining data connectivity, energy analytics, and intelligent motor control, VSDs make industrial operations cleaner and more efficient.

At DAS Company, we see each drive system not only as a component but as an intelligent energy node within a connected industrial ecosystem.

Conclusion

Variable Speed Drives represent one of the most effective methods to reduce industrial energy consumption, lower emissions, and improve reliability.

With the engineering and commissioning expertise of DAS Company, industries achieve:

DAS Engineering Automation Solutions

DAS Company integrates Variable Speed Drives into industrial systems with precision engineering and real-world expertise — powering the transition to smarter, energy-efficient, and sustainable manufacturing.